Fast familiarization with the system

Do the following actions to compute a toolpath and to generate an NC-program in a short term. The typical actions sequence allows you to get to know SprutCAM X quickly.

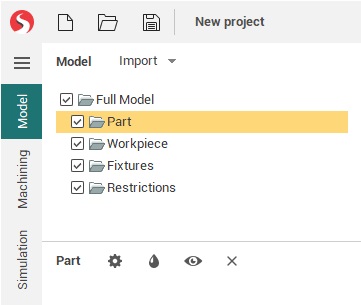

Set the working mode to < Model > by selection of the same name tab sheet on the main panel .

Import a model from the geometrical data exchange file . To do so, just click the

button and select the file you want in the window. The model import will be processed in the active folder. Therefore, before the import starting activate please the < Full Model/Part > folder for the part model import, < Full Model/Workpiece > for the workpiece and < Full Model/Fixtures > for fixtures etc. It is a good idea to make all modifications of the geometrical model before the machining sequence definition because of the default parameters value are choosing according to the part and workpiece at the operation creation moment.

button and select the file you want in the window. The model import will be processed in the active folder. Therefore, before the import starting activate please the < Full Model/Part > folder for the part model import, < Full Model/Workpiece > for the workpiece and < Full Model/Fixtures > for fixtures etc. It is a good idea to make all modifications of the geometrical model before the machining sequence definition because of the default parameters value are choosing according to the part and workpiece at the operation creation moment.

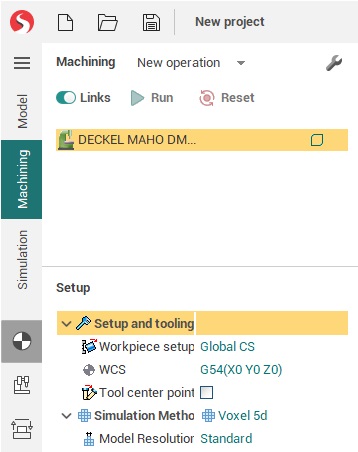

Set the working mode to <Machining> by selection of the corresponding tab sheet on the main panel:

Check the machine type and its parameters ; edit them if it is necessary. The available operation set depends of the machine type. For example, lathe operations only are available for the lathe machine, milling operations only – for the milling machine but the both operation types can be applied for the turning and milling centre.

Form the < Part > the < Workpiece > and < Fixtures > for the root node of the operations list if the models definition demands of some addition constructions. It is possible to make prisms and bodies of revolution that are based on curves and references items (box or cylinder that is circumscribed on the part for example) in addition to the imported models.

Create a new operation (or several operations). To create an operation, press the

button and select the new operation type in the opened window. The newly created operation will be added into the < Machining > folder of the root node. The new operation is set as current and it is ready for editing and execution.

button and select the new operation type in the opened window. The newly created operation will be added into the < Machining > folder of the root node. The new operation is set as current and it is ready for editing and execution.

Define the operation parameters. When creating an operation the program sets < Part > and < Fixtures > as references to models of the same name of the previous operation. The references for the first operation are to the root node models. < Workpiece > is set as a reference to the material that remained after the previous operation machining. < Job assignment > is the full part as default. SprutCAM X automatically defines all other operation parameters according to the foregoing geometrical data. In many cases, the new operation can be immediately executed. You can check or alter operation parameters on the panel in the bottom-left side of the main window or in the windows that are opened by the < Parameters > button click.

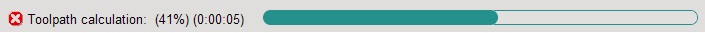

Start operation execution by clicking on the

button. On the process indicator you will see how much of the calculation has already been completed. By clicking within the indicator area, you can stop the process.

button. On the process indicator you will see how much of the calculation has already been completed. By clicking within the indicator area, you can stop the process.

The toolpath calculating rule is to machine the < Job assignment > by the defined strategy with control of the < Part > and < Fixtures >. Roughing operations remove all covering material of the < Workpiece > to do that. The workpiece checking is optional for all finishing operations. If the workpiece is taken into account then toolpath appears for the job assignment areas where the rest material of the workpiece presents else, this one appears for the whole job assignment.

You can estimate the machined piece by turning on < Machining result visibility >

on < Visibility panel >.

on < Visibility panel >.

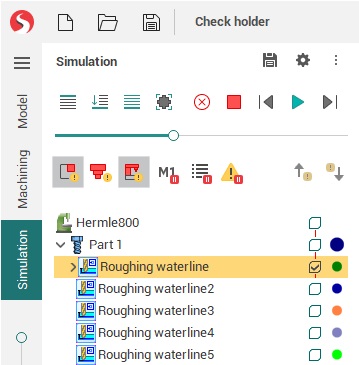

Check the obtained toolpath block by block in the < Simulation > mode . Select the corresponding tab sheet on the main panel and click on the

button to start the simulation process. If it is necessary, then change operation parameters and recalculate them.

button to start the simulation process. If it is necessary, then change operation parameters and recalculate them.

Run the < Postprocessor > by the

keystroke at Machining mode. The postprocessor window will be opened. Select a CNC system (choose postprocessor file with the *.sppx extension) and click the < Run > button. You can see the NC program name in the < Output file > field. As default, the file has a name of the current project and an extension that is set in the selected postprocessor.

keystroke at Machining mode. The postprocessor window will be opened. Select a CNC system (choose postprocessor file with the *.sppx extension) and click the < Run > button. You can see the NC program name in the < Output file > field. As default, the file has a name of the current project and an extension that is set in the selected postprocessor.

Save the project by clicking on the

button of the main tool bar . You can choose the project save mode by the slider position. The project size will be bigger if the saved data is more detailed.

button of the main tool bar . You can choose the project save mode by the slider position. The project size will be bigger if the saved data is more detailed.

You can load a previously created project by clicking on the

button on the main tool bar.

button on the main tool bar.