Tapping cycle G84 <W5DTap>

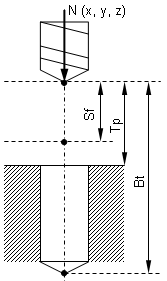

Tapping cycle <W5DTap(484)> (G84) performs rapid approach to the <Z return> level, thread tapping with subsequent retraction at work feedrate with reverse spindle rotation.

G84 tapping cycle includes:

Rapid approach to the hole center at the <Z return> level.

Rapid travel to the <Z safe level>.

Work feedrate motion the <Z min> level.

Spindle reverse rotation and work feedrate trave to <Z safe> level.

Rapid retract to the <Z return> level.

Restore spindle rotation direction and speed.

If the appropriate setting is enabled, then tap retracts to break / remove chip during the cycle execution. Way to break chips is determined by CLD [20] parameter.

CNC-systems often have different tapping canned cycles for fixed and floating socket types. Socket type is specified by the <CLD[19]> (CLD.CLParams(17)) parameter.

Parameters:

|

Description |

||

|

CLD[1] |

CLD.SubCmd |

Command type: ON(71) – canned cycle on, CALL(52) – canned cycle call, OFF(72) – canned cycle off. |

|

CLD[2] |

CLD.SubType |

Canned cycle type identifier: W5DTap(484). |

|

CLD[3] |

CLD.CLParams(1) |

Nx, X coordinate of the tool normal vector |

|

CLD[4] |

CLD.CLParams(2) |

Ny, Y coordinate of the tool normal vector |

|

CLD[5] |

CLD.CLParams(3) |

Nz, Z coordinate of the tool normal vector |

|

CLD[6] |

CLD.CLParams(4) |

Sf, Normal distance from current tool position to the safe plane level |

|

CLD[7] |

CLD.CLParams(5) |

Tp, Normal distance from current tool position to the hole top level |

|

CLD[8] |

CLD.CLParams(6) |

Bt, Normal distance from current tool position to the hole bottom level |

|

CLD[9] |

CLD.CLParams(7) |

Work feed measurements: 0 – mm/rev, 1 – mm/min |

|

CLD[10] |

CLD.CLParams(8) |

Work feed value |

|

CLD[11] |

CLD.CLParams(9) |

Approach feed measurements: 0 – mm/rev, 1 – mm/min |

|

CLD[12] |

CLD.CLParams(10) |

Approach feed value |

|

CLD[13] |

CLD.CLParams(11) |

Return feed measurements: 0 – mm/rev, 1 – mm/min |

|

CLD[14] |

CLD.CLParams(12) |

Return feed value |

|

CLD[15] |

CLD.CLParams(13) |

Delay at the bottom level in seconds |

|

CLD[16] |

CLD.CLParams(14) |

Delay at the top level in seconds |

|

CLD[17] |

CLD.CLParams(15) |

Thread step |

|

CLD[18] |

CLD.CLParams(16) |

Initial spindle angle in degrees (for multistart threads) |

|

CLD[19] |

CLD.CLParams(17) |

Tap socket type: 0 – floating (compensative), 1 – fixed (uncompensative) |

|

CLD[20] |

CLD.CLParams(18) |

The way to break chip : 0 – without chip breaking, 1 – chip removing, 2 – chip breaking |

|

CLD[21] |

CLD.CLParams(19) |

St, chip breaking step value |

|

CLD[22] |

CLD.CLParams(20) |

Dg, each iteration chip breaking step degression |

|

CLD[23] |

CLD.CLParams(21) |

Dc, before drilling deceleration value for each step |

|

CLD[24] |

CLD.CLParams(22) |

Ld, each step lead out value for cutting process breaking |

|

CLD[50] |

CLD.CLParams(48) |

What spindle is used to machining: 1 - driven tool, 2 - workpiece spindle (lathe). |

See also: