Machining step

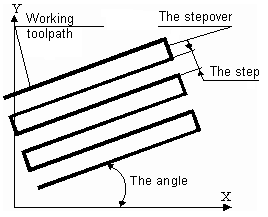

The machining step defines the distance between two neighboring work passes of the tool. Depending on the operation type the step can be assigned in vertical and/or in horizontal direction. In the roughing operations, normally, the user can assign both the vertical and the horizontal steps; in finish operations – the step for the vertical direction, in plane and drive – in the horizontal. The step value defines the height of the remaining material scallop between two neighboring passes.

For more convenience, the step value can be assigned by several methods.

By the real step value. The value is assigned by the absolute value and does not change upon correction of other parameters;

In percents from the mill diameter. The real step value makes the defined percent from the tool diameter and accordingly alters upon changing the tool;

By the number of passes. The whole machining range is divided into the defined number of equal parts. The real step value will change upon alteration of the machining range. This means that the step value in the vertical direction will alter when the top and/or the bottom machining levels are changed;

By scallop. The step between neighboring tool passes is not permanent, it depends on the geometrical parameters of the tool and the shape of the model surface of the being machined. The step value is selected so that the height of the scallop of the remaining material between neighboring work passes does not exceed that defined. When choosing the step by the height of the scallop in the vertical direction it is also necessary to additionally assign the maximum step, and in the horizontal – the minimal. In case if the calculated step value exceeds the defined limits, then its maximum value will be used;

All the above methods arrive at the same results. Upon changing the value for calculation of the real step, the system will automatically recalculate all values for definition of the same step by other methods. It allows, for example, estimating the real step value when assigning it as a percentage of the tool diameter.

Irrespective of the assignment method, the real step value must be more than zero.

The step in the vertical direction can be assigned in the <Parameters> page, and in the horizontal – on the <Strategy> page.

See also:

Definition operation parameters