Counter spindle machining

Counter spindle machines allow machining of parts in single fixing, reducing idle time and increasing machining precision. Also, counter spindle presence eliminates need for locating tools. There are machining centers with two machining turrets in addition to counter spindle. These machines optimize idle time and virtually replace two machines.

SprutCAM X can create NC-programs for counter spindle machining for both lathe and lathe-milling machining technologies.

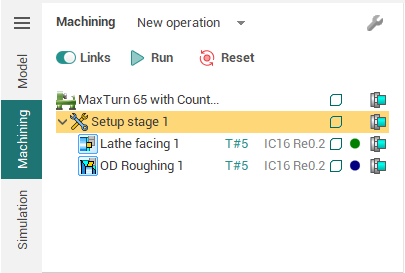

For a more detailed explanation of SprutCAM X approach to the counter spindle machining please take a look at the following sample project of shaft machining.

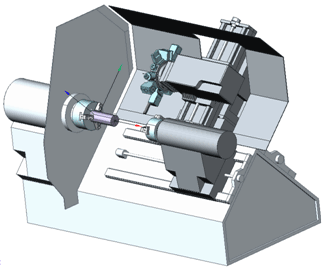

The machine is the <MaxTurn 65 with Counter Spindle>.

What is necessary to know before developing counter spindle machining process:

Spindle in which the machining will start.

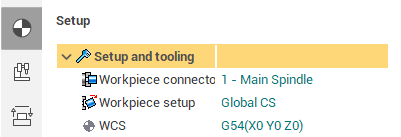

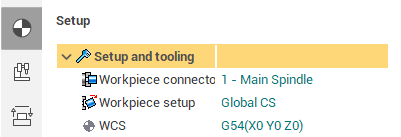

Workpiece coordinate system (position in which the workpiece will be set). In the properties of this coordinate system specify it as <Machine coordinate system>, G54 for example. It is recommended to bind workpiece coordinate system to the non-fixed workpiece end.

First create the Setup Stage or Part operation which defines the initial position of the workpiece. Workpiece coordinate system and spindle where workpiece is fixed are specified on the <Setup> tab in the <Workpiece connector>, <Workpiece setup> and <WCS> fields respectively.

After defining workpiece location the exposed part elements should be machined.

Please note: To avoid mistaking active spindle in consequent operations specify <Frоm the previous operation> value for the <Current workpiece holder> field.

To refix workpiece from one spindle to another create a "Stage" or "Part" operation. For more information on the multi part projects see Multi parts projects. To simulate the transfer of the part from the main to counter spindle you can use the Turn take over operation.

After refixing create operations to machine the rest surfaces. Operations can be either lathe or lathe-milling.

In the Setup Stage or Part operation specify that machining is performed in another counter spindle. To do this specify, <2-Counter Spindle> in the <Workpiece connector> field, and specify new coordinate system in the <WCS> field.

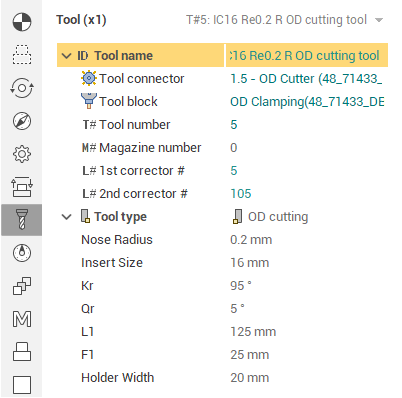

Specify the appropriate hand of tool in the toolholder parameters on the <Tool> page.

SprutCAM X simulates both the machining operations and auxiliary operations so that user can control workpiece and machine movement and provide necessary modifications.

See also: