Turn take over

Turn take over is the special kind of pick and place operation designed to use in the MTM or swiss-lathe project template.

MTM projects and how to create it is shown in the video below.

The main difference of the Turn take over operation from the simple pick and place is that it takes Workpiece connector and Setup CS automatically from the next part of the project. Also the set of operation parameters is adapted specifically for the lathe or swiss-lathe type of machining.

Turn take over parameters

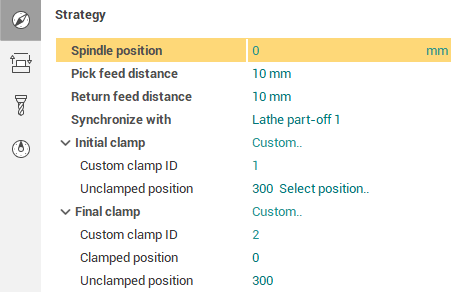

Spindle position

Initial main spindle position in the physical coordinates for this operation (if the machine is lathe/swiss-lathe with 2 spindles). It is outputted in the return section of the previous operation.

Pick feed distance

The length of the movement which is done using the engage feed before picking the part.

Return feed distance

The length of the movement which is done using the retract feed after picking the part.

Synchronize with

The <Wait> CLData command will be inserted which allows this operation to stop any machining until the specified operation is finished.

Clamp parameters

Select (optionally) the clamp devices which are used to hold the part during different stages of the Turn takeover. For more information about the clamp control parameters, see the Clamp devices control article.

Example project(s)

See the Turn-Milling/Hanwha and Turn-Milling/Takeover sample projects for an example of the part takeover between the spindles.

See also:

Machine requirements for part moving operations