Multi parts projects

Part as a group of operation

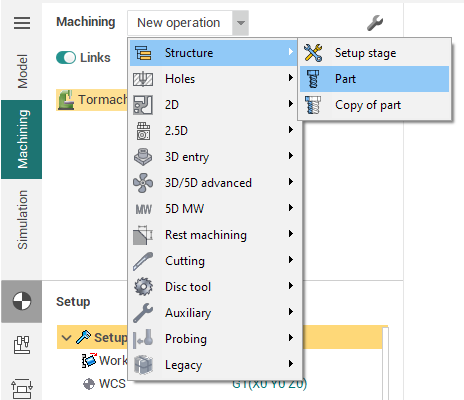

If you want to prepare the project with the several parts you need to create the special group of operation named as “part”.

In the CAM tree the part group is always located inside the root (machine) or inside the setup stage, if it was created. If at least one part was created then all machining operations will be created inside the parts. All the operations inside the part group are working over one part. Usually for the part group it's neccesary to define the specific part geometry, workpiece, fixtures, setup location and origin. Operations inside will use these parameters. as the common parameters of the part.

Sequencing mode

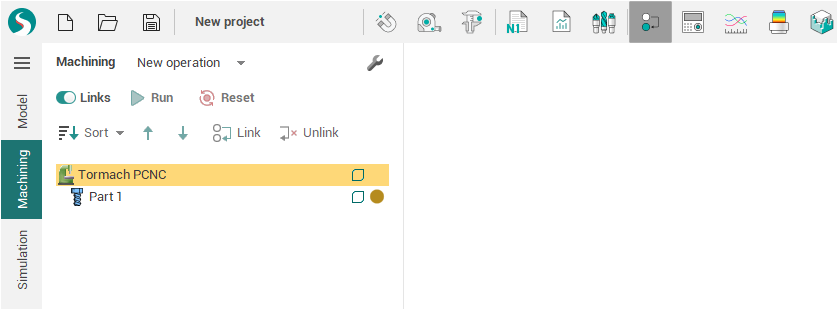

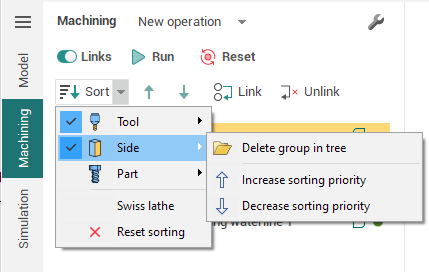

Operations inside the part group define the machining sequience of this one part only. In fact it defines the residual workpiece material for every next operation. If the project contains more than one part then the real machining sequence can be redefined, for example to minimize the tool changes or the tombstone rotations. Use the button on the main panel to switch on the sequencing mode. In this mode the reordered operations tree is shown.

By default the operation are sorted automatically to minimize the tool changes. It's possible to change the machining order manually by drag-n-drop or with the arrow buttons on the sequencing panel. Arrow button moves the selected operation before/after the previous/next one. Sort button restores the automatical sorting. The rules for the automatic sorting are defined in the next popup menu

The links between the operations can not be calculated before the real machining order is set. Therefore the links calculation was separated from the main calculation process. Full workflow for the multipart projects contains the next steps:

Placements of the part in the work space of the machine

Design of the the machining process for every part. Calculation of the tool path without the links (approaches and returns).

Simulation of the process with the disabled sequencing mode, to check the correctness of the workpiece change etc.

Reordering of the operations in the sequencing mode.

Calculation of the links between the operations.

Simulation of the process in the sequencing mode to check the links and the tool changes between the operation.

Tool path generation

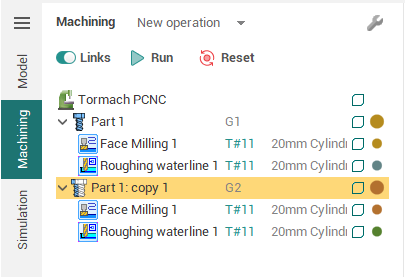

Part copies

Copy of part is the special kind of simple part. It's designed to prepare the project with the several identical parts. Usually it can be done with the next steps:

Create the prototype part. Add operations, that are neccesary for the machining.

Create copy of part. If the project contains more than one part then the copy of the current selected part will be used as prototype.

Assign the workpiece setup and workpiece CS for the copy.

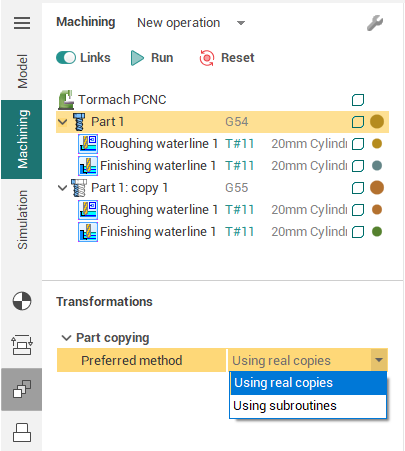

Copy of part is a group of operations, that is syncronized with the prototype group (part). It's not possible to add or delete the operation inside the copy. If an operation is created/deleted in the prototype part, then the copy of this operation will be created/deleted in all part copies. Copy of part contains inside the special operation copies. Operation copy doesn't calculate the toolpath itself. It just apply the toolpath of the prototype operation to the place of the part copy. So if reset the prototype operation then all copies of this operation will be reset. Recalculation of copies must be started manually.

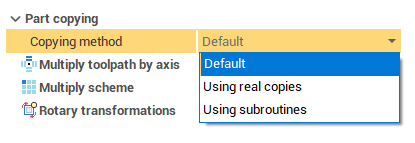

There is the possibility to output the copies machining as the subroutine calls. The way of output is defined in the parameters of the prototype part. Before usage the subroutines be sure that your postprocessor supports it.

You can set individual copy parameters for each operation in the group.