Tapping cycle, tapping with chip breaking and removing (G84, W5DTap(484))

Tapping cycle performs rapid approach to the <Z return> level, thread tapping with subsequent retraction at work feedrate with reverse spindle rotation.

<G84> tapping cycle includes:

Rapid approach to the hole center at the <Z return> level.

Rapid travel to the <Z safe level>.

Work feedrate motion to the <Z min> level and then <Spindle reverse>. If you select the tapping with chip removing or breaking strategy, the finish depth of the hole will be reached in several iterations.

Work feed travel to the <Z safe> level.

Rapid retract to the <Z return> level.

Restore spindle rotation direction and speed.

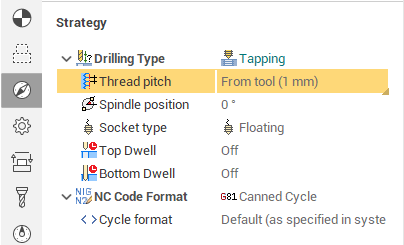

The cycle parameters are defined in the <Thread parameters> panel. The <Thread pitch> defines the pitch in millimeters or inches. It depends on the current measurement units. The <Spindle position> is used for the multistart threads and defines the start <Spindle position> in degrees.

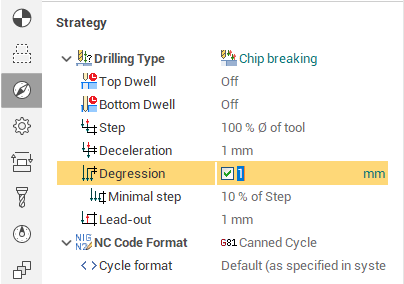

<Chip breaking parameters> panel defines the <Step>, <Deceleration> and <LeadOut>. The step can be specified by different ways:

<Distance>. The step is equal to the input value.

<Count>. The value defines the quantity of the tool pecks. The step is calculated as the hole depth divided into the peck count.

<Percent>. The step is specified in the percent of the tool diameter.

If the <Depth degression> is checked then the depth of every following peck is reduced on the defined value, else the step is constant. The step reduction occurs until its value is not less than <Minimal step>. Minimal step is a percentage of the first step value.

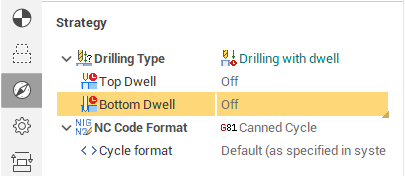

The time of delay is defined on the <Dwell> panel in the field <Bottom dwell>. The time can be specified in seconds or in the numbers of the tool revolutions. In the last case the time is calculated automatically using the defined tool RPM. Delay is absent if the bottom dwell is off.

Some numerical controls has different cycles for the different socket type. So the socket type can be defined as floating or fixed.

See also:

The ways of the holes machining