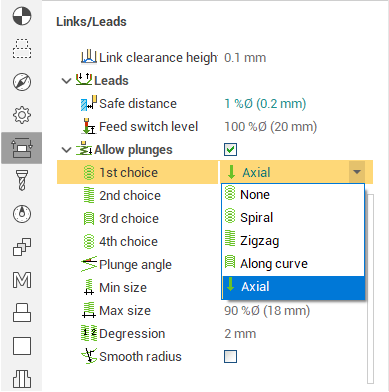

Plunge methods of mill operations

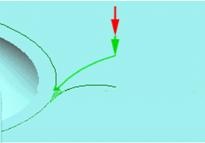

When it is impossible to approach the machining area from the outside, the system automatically generates a plunge movement to the first point of the work pass. A plunge is a toolpath section along the Z axis within the workpiece body. The <Plunge> is performed as follows:

Tool approach to the XY plunge point at the safe plane of the operation.

Traverse vertically at rapid feed to the safe level or the safe distance before cutting begins (depending on settings). The safe level is the Z top level of the current coordinate system. The safe distance is the distance to the start of the defined plunge.

Vertical descent at the approach feeds into the beginning of the defined plunge.

The selected plunge method is applied at the approach feed to the approach point.

Approach starts.

The following plunge methods are available in the system:

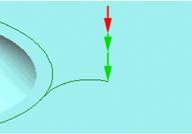

<Axial>. Performed along the vertical straight to the first point of approach.

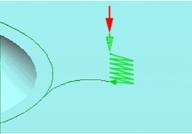

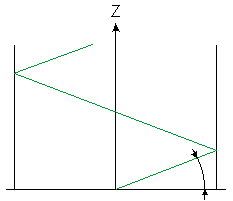

<Zigzag>. The tool performs reciprocal movements along a straight section, connected to the first approach point. The length of the section is a user-defined option.

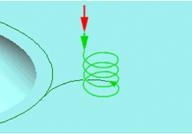

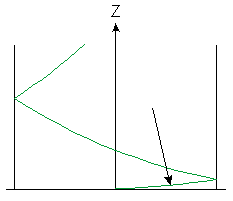

<Spiral>. The tool performs a helical motion along a circle, connected at its last point with the first approach point. The radius of the circle is a user-defined option.

<Along approach curve>. The tool plunges along the approach curve. The plunge move is completed at the end of the approach move.

For the last three plunge types (<Zigzag>, <By spiral> and <Along approach curve>) the system applies the selected Z movement rule. Two motion types are available: <Angular> and <Radial>:

<Angular>. The speed of the vertical movement of the tool is constant. The parameter is defined as the angle between the XY plane and the vertical tool (Z) plane.

<Radial>. The vertical tool movement is performed according to the sinusoidal rule, where the depth variation speed at the last point is equal to zero. The parameter is defined by an arc radius, the center of which is located parallel to the Z-axis from the starting point of the toolpath.

You can define more than one type of plunge for one operation by set check field for this plunge type. At this case, you can arrange preferred types manually using button

. Upper plunge type at list is more preferred for system.

. Upper plunge type at list is more preferred for system.

See also:

Approach, retraction, and plunge methods