Corners cleanup

The rest machining operation takes the diameter of the previous tool as a parameter and generates passes where the previous tool would leave unmachined material.

Parameters

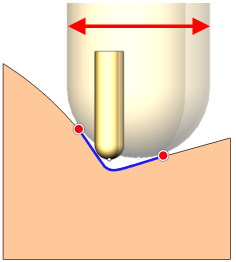

Previous tool diameter

The diameter of a spherical mill which is used for the rest material calculation.

Cut depth

The maximum cut depth for a cut

Step

The maximum step-over between passes

Strategies

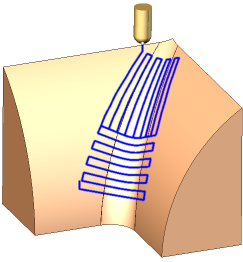

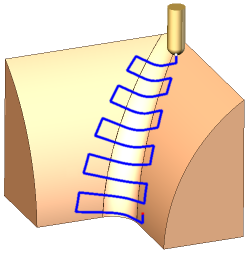

Along

The passes are generated along the corners.

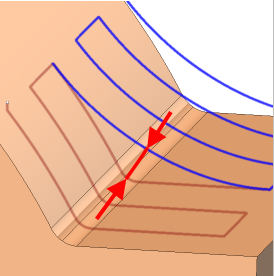

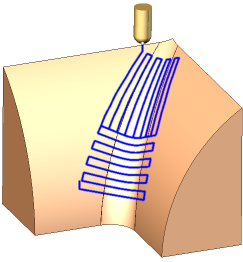

Across

The passes are generated across corners

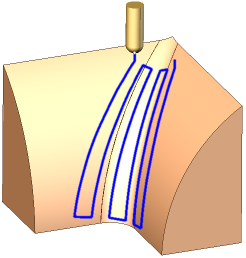

Combined

For shallow areas - along passes are generated, for steep areas - across passes are generated.

Job zone

Machining surfaces

The passes are generated only on places where the tool contacts the machining surfaces. If the machining surfaces are missing, the toolpath is generated against the whole part.

Bottom level

A bottom level can be set for the passes

See example of operation on YouTube: