Hole pocketing cycle (W5DHolePocketing(491))

The cycle is used to machine holes which diameter is greater than the tool diameter. The pocketing is performed by layers. The tool cuts in along a spiral to each layer and then expands the hole to the desired diameter by moving along Archimedes spiral with finishing pass along the circle. The Archimedean spiral is approximated by the circle arcs.

Hole pocketing cycle includes the following:

Rapid approach to the center of the hole at the <Z retract> level.

Rapid motion to the <Z safe> level.

Work feedrate spiral cut-in to the <Z machining depth>. Spiral diameter <Ds> is specified in the percents of the tool diameter. The plunge is defined by the Angle <a> or Step <Hi>.

Archimedes spiral with <Step S> motion at that level until the tool axis has reaches the circle with diameter equal to hole diameter reduced by the tool diameter.

Finishing pass along specified above circle without level change.

Repeat previous three steps until desired hole depth is machined with travel to the next cut-in point without level change.

Return to the hole center.

Rapid travel to the <Z retract> level.

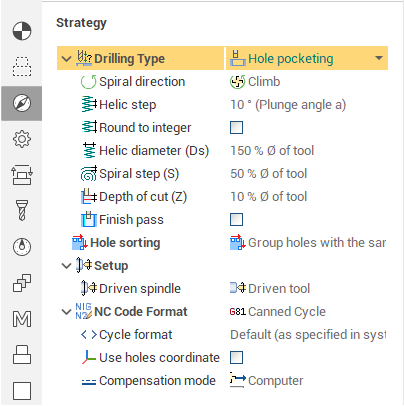

Pocketing parameters panel defines the parameters of the hole pocketing cycle.

Spiral direction defines the torsion direction. It can have the next values:

<Right>. The Spiral is twisted right. The tool is rotating clockwise if watched from above.

<Left>. The spiral is twisted left. The tool is rotating counter clockwise if watched from above..

<Counter>. Spiral twist direction is determined by the spindle rotation direction and corresponds to the up cutting milling. When counter pocketing milling tool rotation direction and spiral direction are opposite to each other.

<Follow>. Spiral twist direction is determined by the spindle rotation direction and corresponds to the down cutting milling. When counter pocketing milling tool rotation direction and spiral direction are coincident.

Note: The direction of the tool rotation is defined on the Tool page of the operation parameters dialog.

The spiral step is defined in the field with the same name in the Pocketing parameters panel. If the Plunge angle (a) is selected in the box the step value depends on spiral radius and specified as the plunge angle in degrees. If the distance is selected then the value is a step in the current measurement units (mm or inches).

The round turn count to integer recalculates the step value to get the integer value of the coils.

The depth of cut (Z) defines the distance between the horizontal layers. It can be specified by different ways:

<Distance>. The depth is defined as absolute value in the current measurement units (mm or inch).

<% D of tool>. The depth is defined as the percents of the tool diameter.

<Count> The value defines the layers quantity. So the step is calculated as the hole depth divided into the layers count.

The plunge spiral diameter (Ds % of tool) is specified in the percents of the tool diameter. The Archimedean spiral step (Ds % of tool) is specified in the percents of the tool diameter also.

If the finish pass is enabled then the additional circle pass is generated before the final pass on every layer. The value near the Finish pass defines the stock for the final pass in current units (mm or inch). This feature allow to remove the equal stock of final pass.

See also:

The ways of the holes machining