Toolpath interpolation

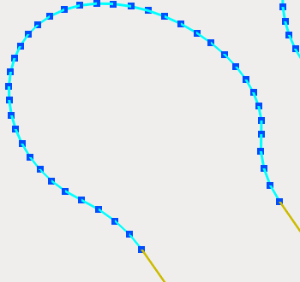

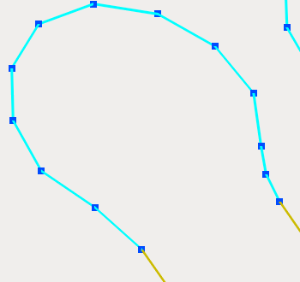

Using interpolation is one of the main ways to modify the path, allowing you to adjust smoothness and the concentration of points on trajectory.

Interpolation is available in operations:

Disc cutting 6D

Disc roughing

Rotary roughing

Sawing

Morph

5D Surfacing

Scallop

3D Helical

Rotary machining

5D Contouring

6D Knife cutting

Corners cleanup

Pencil

Cladding 5D

3D contouring

Welding 5D

Roughing drive

Drive

Plane

Roughing plane

Optimized plane

Complex

Combine

Chamfering

5D by meshes

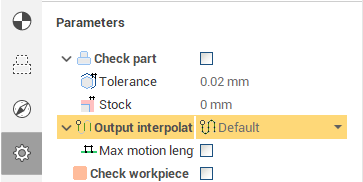

You can enable interpolation on the "Parameters" tab in the inspector window:

Interpolation options:

Default - the system selects the type of interpolation depending on the parameters of the machine and the trajectory type. If the machine supports spatial arcs and the path of operation is 5 or 6 axial, then the "Spatial arcs" mode will be used. If the machine does not support spatial arcs, but supports arcs in the XY / YZ / ZX planes, and the path is 3 coordinate, then the "Planar arcs / Helics" mode will be used. If the machine does not support arcs, the "Cuts" mode will be used.

Off - output only by cuts without changes.

Cuts - Cuts interpolation with a selected tolerance.

Planar arcs/helics - arcs interpolation in the XY / YZ / ZX planes with the Circle command (depending on the operation).

Spatial arcs - arcs interpolation using the "Multiarc" command, if supported by the machine.

Fixed length cuts - output with cuts of a selected length. Valid only for a smooth path. Sharp corners can be cuts.

Fixed length spatial arcs - output by "Multiarc" arcs of a selected length. Only permissible for a smooth trajectory.

Spatial arcs(old method) - output arcs with the "Multiarc" command (old method) in those operations where it was previously.