Multiply group

This method of copying is outdated, it's recommended to use Part copies.

The operation is intended for machining of sample pieces with repeating patterns. It allows to calculate a tool path for one pattern by any combination of operations and then to repeat this machining a necessary amount of times for other patterns.

Source operations must be added into the multiply group (by analogy with an operations group). A toolpath of the operations will be transformed or multiplied. The transformation mode and the copying scheme are arranged on the Strategy page of the operation parameters window.

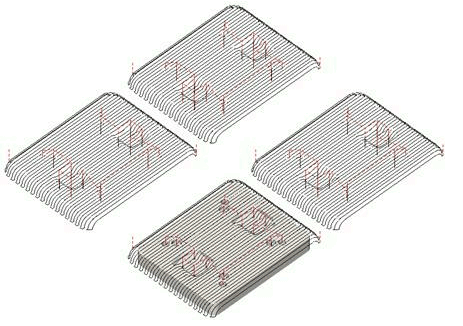

The following spatial transformation types and copying schemes are available:

<Two dimensional array>. Repeating patterns of a toolpath place as a rectangular grid, with distance between elements to the equal values given in fields X and Y. The Angle value sets an inclination angle of a grid relative to horizontal;

< Two dimensional array (manually) >. Repeating patterns of a toolpath place manually. The count of elements and coordinates of each element are set by user;

<Round array>. Repeating patterns of a toolpath place along a circle, with the centre in point X and Y, radius R and the angle pitch given in the appropriate field;

< Round array (most distant) >. Repeating patterns of a toolpath place along a circle, with the centre in point X and Y, radius R and the angle pitch given in the appropriate field. Elements are sorted more distantly from each other;

< Round array (manually) >. Repeating patterns of a toolpath place along a circle, with the centre in point X and Y, radius R. The count and the angle of each element are set by user ;

<Axis symmetry>. Repeating patterns of a toolpath symmetrical about the given axis. A point and an angle within a horizontal plane set the axis

<Point symmetry>. Repeating patterns of a toolpath symmetrical about a centre point. Coordinates X and Y set the point of the centre of symmetry;

The amount of rows, lines and columns for all copying schemes (without manually setting elements) is set in the <Columns> and <Lines> fields.

It is possible to set the machining order <By blocks> or <By operations>.

If the machining order is by blocks then repeating patterns of a sample piece will be machined, sequentially one by one. That is, the first pattern will be machined by all indicated operations all over again, and then the same set of operations will be repeated for the subsequent patterns in the appropriate place etc. If the machining order is by operations then all patterns will be machined by the first operation all over again, next by the second operation etc. Machining by blocks is expedient for applying the order of machining, if machining is manufactured by one type of the tool or patterns are located on big distance one by other. An order by operations is optimum for machining by different tools.

Also, it is possible to set the milling type (climb or conventional).

Other way for machining multiply elements is use option multiply toolpath by axis for operation.

See also: