Build kinematic schema

Click Kinematic tab to open kinematic parameters panel.

Kinematics

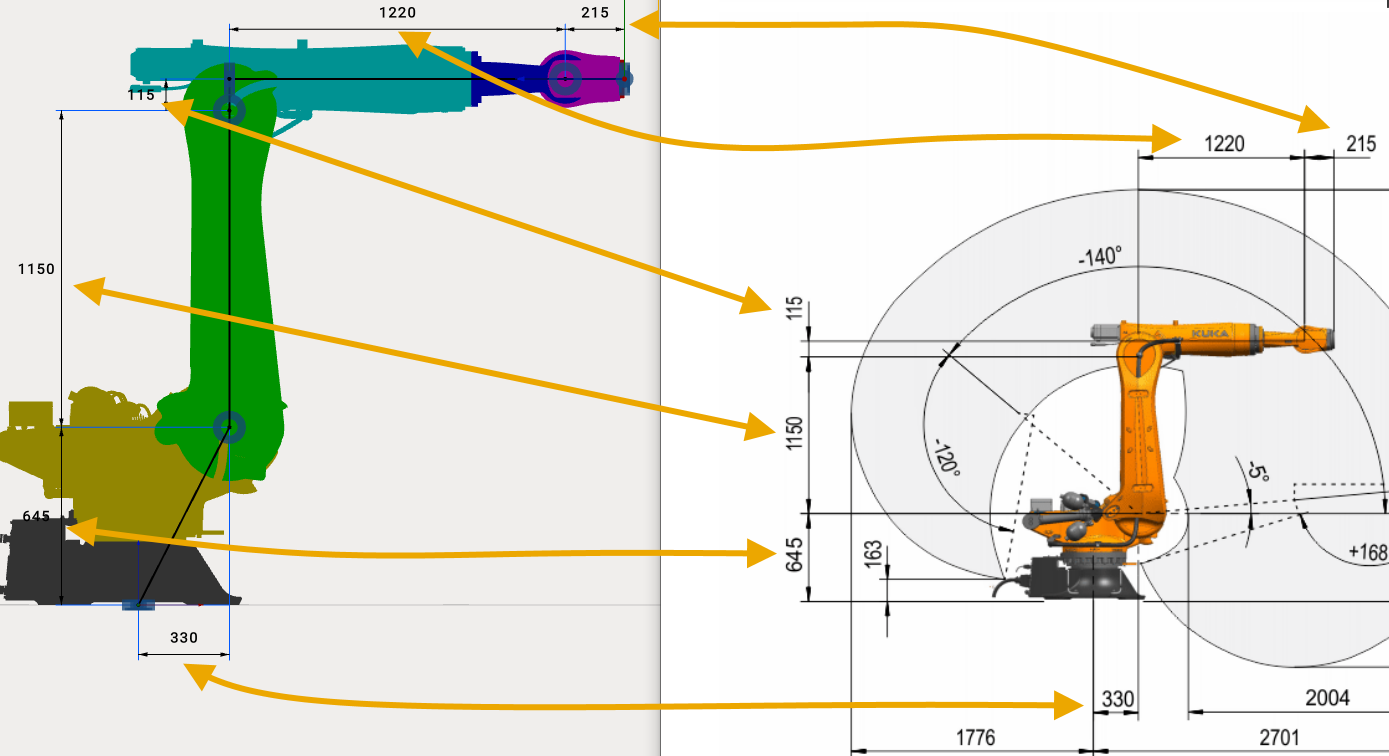

MachineMaker shows current mechanism's 3D model and kinematic schema. It is necessary to build correct kinematic linkage by specifying joints positions.

There are three ways to set joint position:

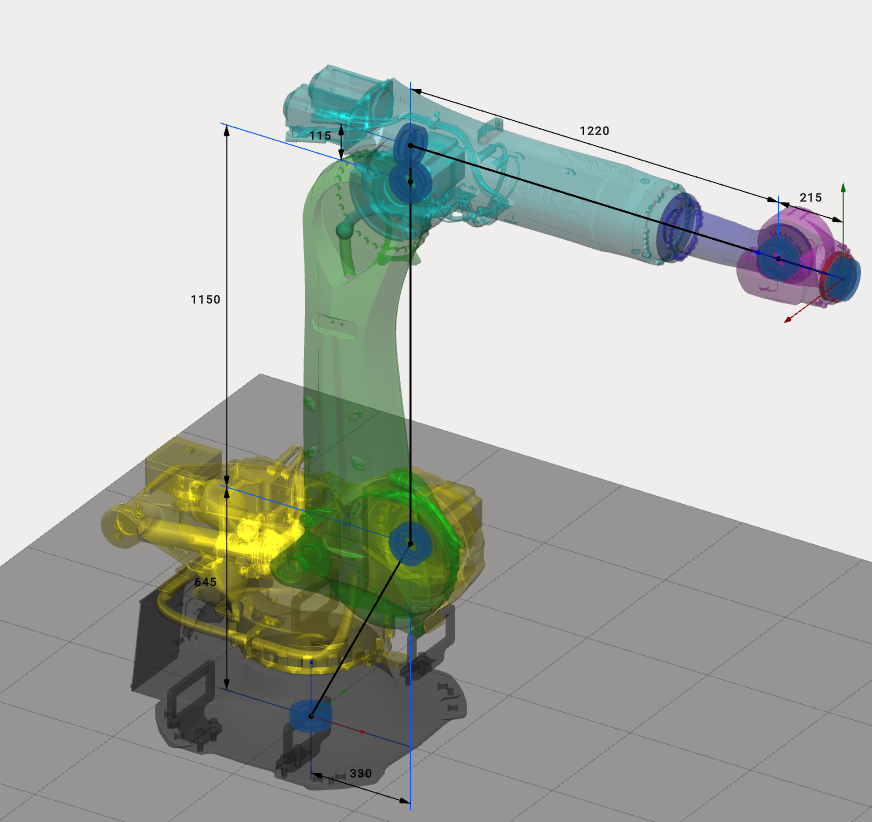

Dimensions

Transformation panel

Drag&Drop and snap points

Dimensions

Click to dimension and enter new value.

Transformation panel

It is also possible to set position of any joint manually. Click joint (blue bearing for rotary joints) and enter move and rotate values to the transform panel at the right bottom corner.

Use Mouse Wheel Scroll to change values on any inputbox or combobox. Hold Shift or Ctrl keys while scrolling values to change values faster or slower.

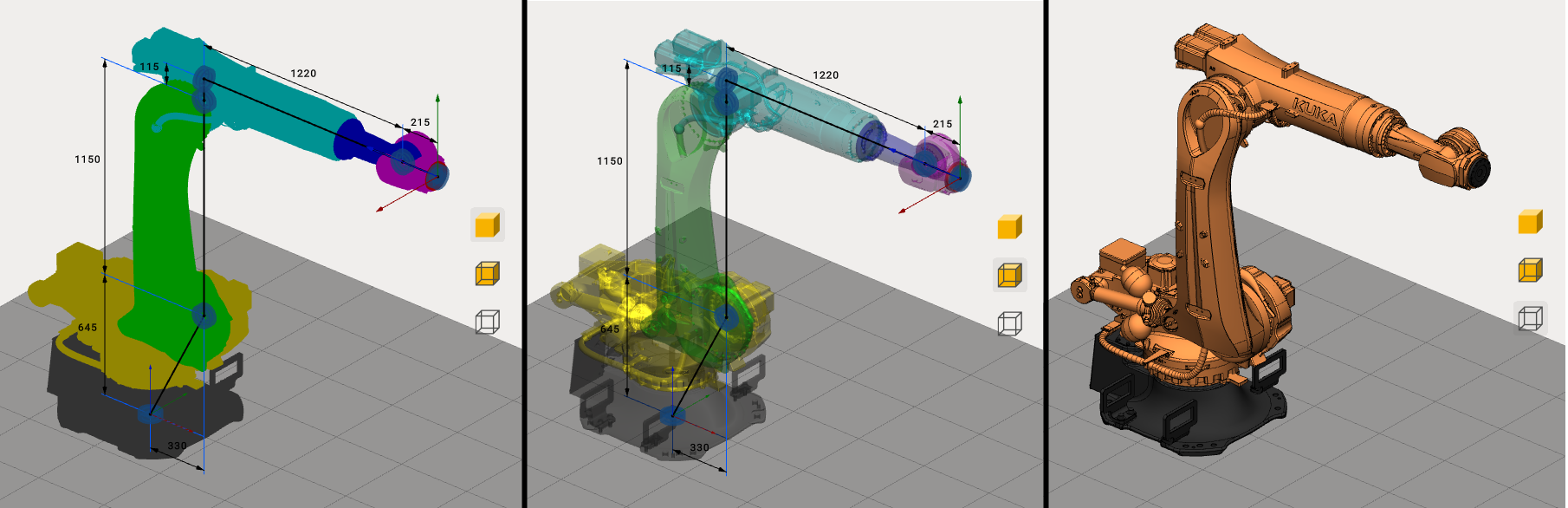

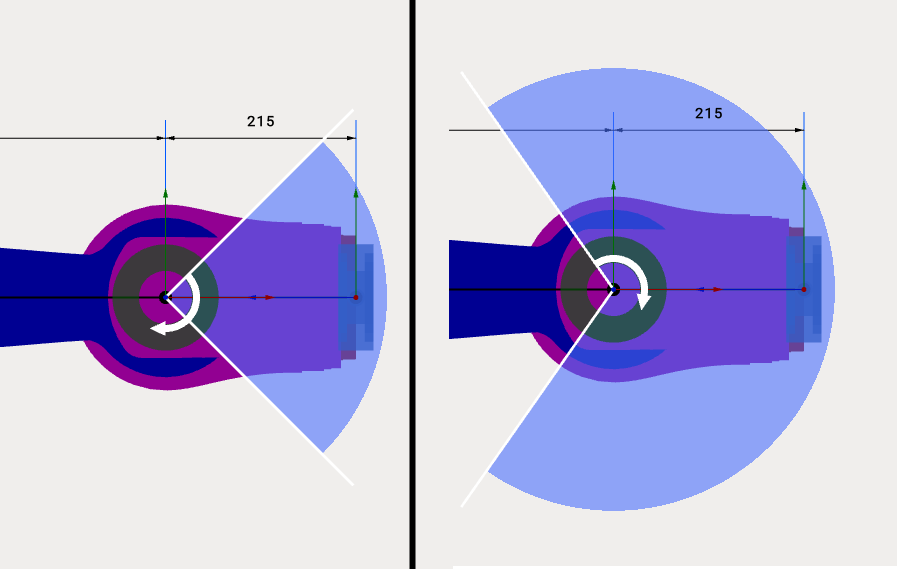

Use Visualisation Panel menu to switch visualisation mode

Drag&Drop and snap points

Hold Left Ctrl key to enter Drag&Drop mode. Drag any joint (blue bearing for rotary joints) or connector (blue point). MachineMaker will show small red snap points nearby. Release mouse button to drop object.

Drag&Drop mode is not available for Robot kinematics. Almost all industrial robots have standart kinematic schema. It is enough to enter several dimensions from DataSheet to completely describe robot kinematics.

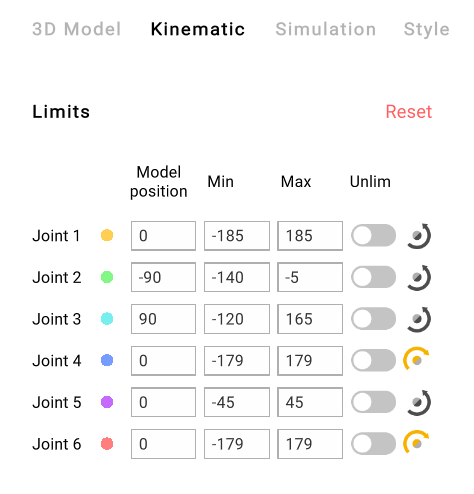

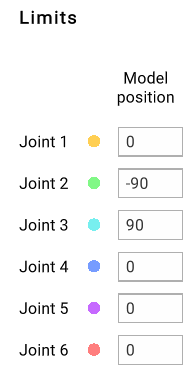

Limits

It is possible to enter limits for each node. You can find this information in DataSheets.

MachineMaker shows joint's minimum and maximum values.

Use  or

or  buttons to change rotation or movement direction.

buttons to change rotation or movement direction.

Use Unlim switcher to allow unlimited rotation for positioners.

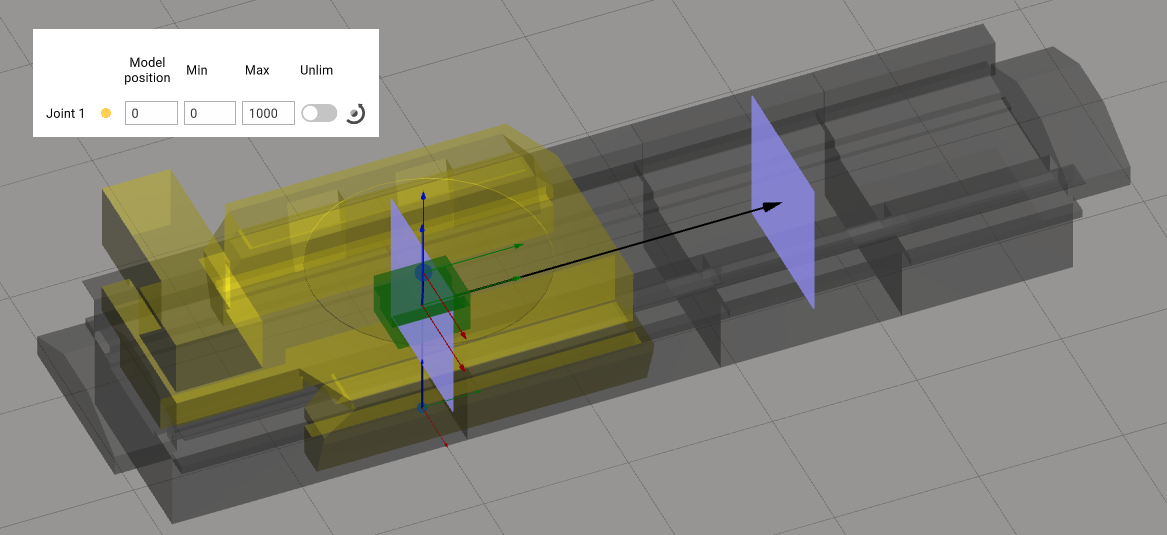

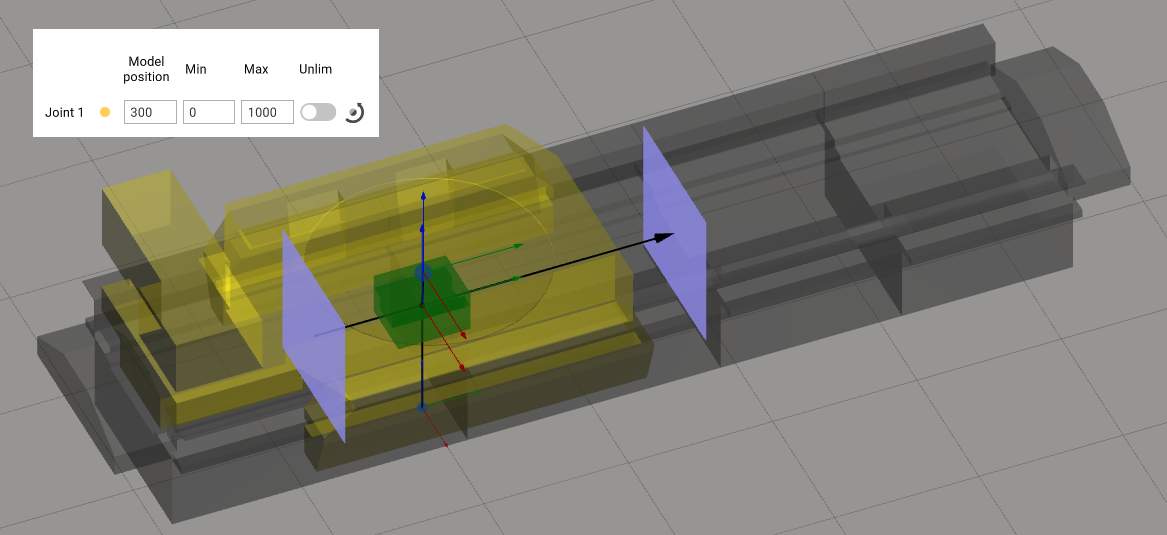

Model Position

Use Model Position to set joint values for current position of imported 3D model. These fields allows you to use CAD files of mechanisms, saved in non-zero positions.

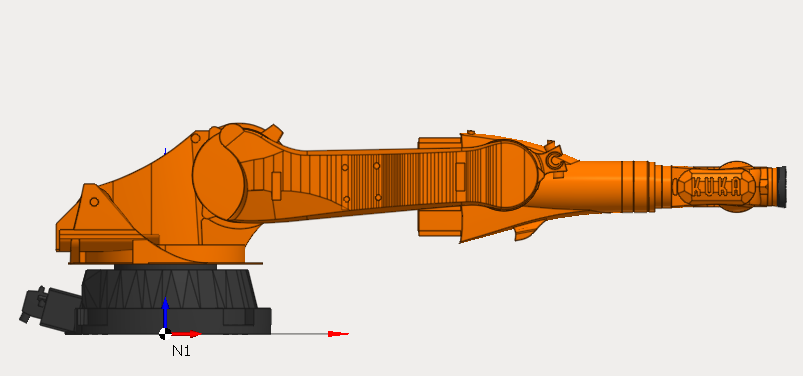

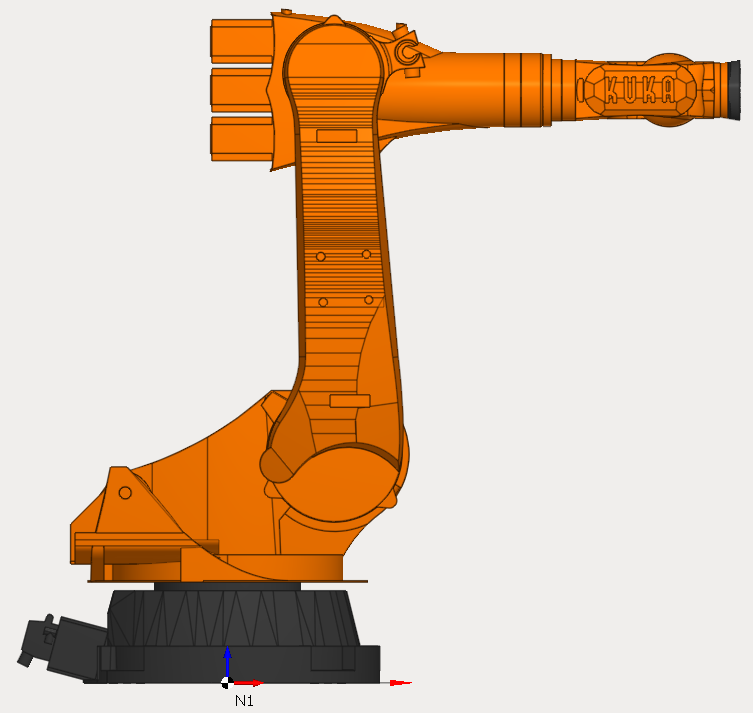

For example here is the zero position of Kuka robots:

But Kuka download center provides only 3D models for non-zero robot position:

So we can just specify Model Position values and use 3D models provided by Kuka. It is not necessary to change them on CAD system.

Model Position is also useful for linear axes.

Model Position is also useful for linear axes.