Job assignment for volume machining operations

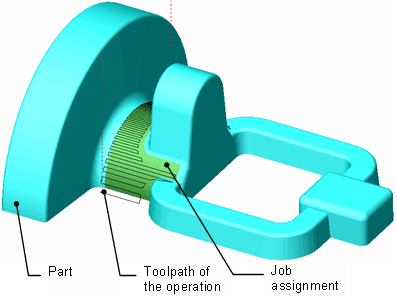

The job assignment of an operation defines the list of elements to be necessarily machined by the operation, while the part in turn is only checked to not produce tool travels involving part gouges; the part geometry itself is not used to generate toolpath. The volume machining operations use faces and meshes as job assignment. This is the list of the volume machining operations:

waterline roughing operation;

plane roughing operation;

drive roughing operation;

waterline finishing operation;

plane finishing operation;

drive finishing operation;

combined operation;

plane optimized operation;

complex operation;

waterline rest milling with clearance;

waterline rest milling;

plane rest milling;

drive rest milling;

plane optimized rest milling;

complex rest milling.

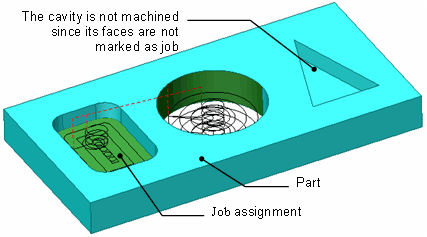

The default job assignment for a volume machining operation is the <Current part>. The same item can be also added to the job assignment by pressing the <Reference> button. As one can see from the name of the item, all the faces of the part will be machined. If only several faces have to be machined those should be added to the job assignment explicitly by pressing the <Add Faces> button. The order the items are listed in the job assignment does not influence the toolpath will be generated.

The job assignment for roughing operations specifies the part fragments to be machined. At that the material that put obstacles to the tool will be also removed. This means that it is no need to specify all the faces of the cavity to be machined as job assignment. It is enough only to indicate the lowest face of the cavity

The job assignment also defines the automatic machining levels. For example, if a wall of a hole is specified in the job assignment then the lowest level to machine will be determined by the lowest point of that surface.

See also: