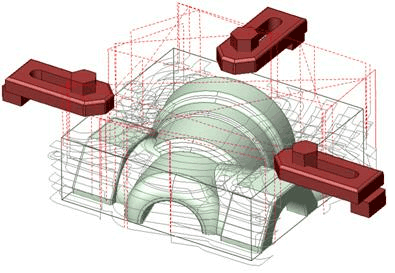

Fixtures

As the <Fixtures> the fixing aids such as chucks, grips, clamps, etc., and the restriction areas of any other nature are usually specified. While calculating a toolpath the fixtures are used as the models the tool should not collide with while machining the part. The fixtures can be constructed from solids, surfaces and features generated from curves. The fixtures of an operation are set to the <Fixtures of the previous operation> by default. If no <Fixtures> are defined then check for collisions is not performed.

All tool movements, irrespective of the operation type, can only be performed outside the borders of the fixtures. The finishing operations can machine only those areas of the model being machined that are located outside the restricted model. The roughing operations can remove material only from outside of the restricting model.

Note: Although the restricting model is not machined, there can be moves between work passes performed along it, and the rough operations perform material removal located outside the restricted model. Therefore, a guaranteed gap between the tool and the real restricting objects should be considered either directly in the geometrical model of the restricting objects, or by the additional stock value. If a restricting model is not defined, then it will be considered that machining can be performed in all areas.

See also:

Defining part, workpiece and fixtures