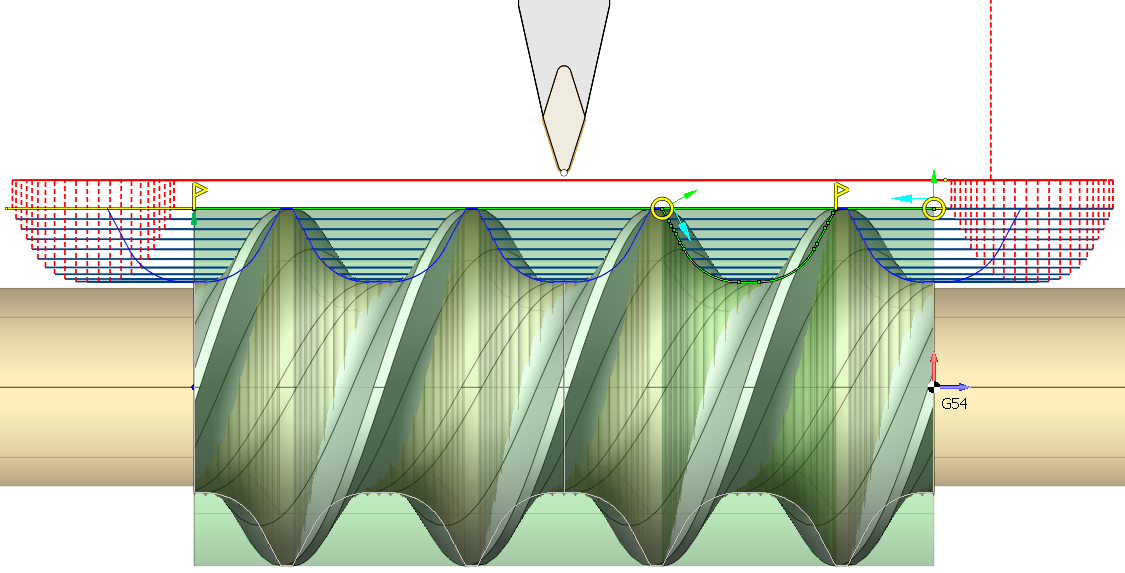

Free form thread

The profile threading operation allows you to make threads whose shape is different from the shape of the tool. This is achieved by removing material inside the entire threaded groove with a series of consecutive passes, the mutual arrangement of which is calculated taking into account both the shape of the tool and the shape of the threaded groove itself.

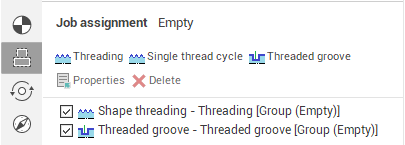

Thus, in contrast to the standard form threading operation, in the job assignment it is necessary to add two items at once.

An item that determines the position of the beginning and end of the thread on the part: Threading or Single thread cycle (depend on desired output format).

An item that defines the shape of the threaded groove - Threaded groove.

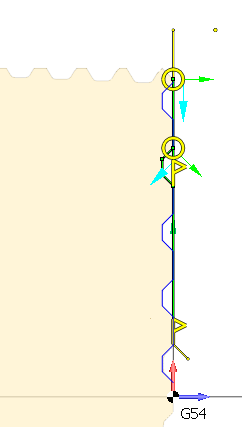

Depending on the orientation of the given profiles, you can get a cylindrical, conical or face thread (archimedean spiral).

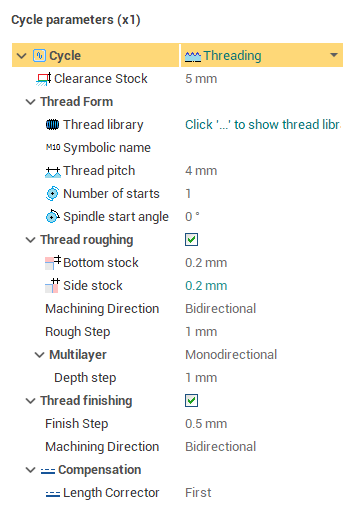

The Properties window for the job assignment item of the free form threading operations has the following parameters.

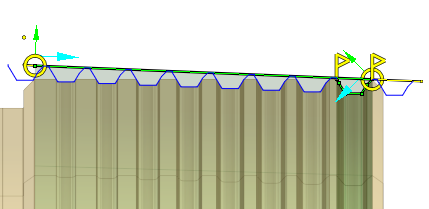

Thread roughing group. If it is enabled then successive passes along the longitudinal axis are performed with a given step.

The Bottom stock and Side stock defines the stock values on the bottom and side walls respectively to leave for finishing.

Rough step – step between two adjacent rough cuts along a thread. It can be set by total number of passes (the common width of a groove divided into the count of passes), or directly by the distance between passes.

The Machining direction parameter defines the order of rough cuts.

Bidirectional.

Alternate.

Forward.

Backward.

The Multilayer parameter allows to remove a rough material by several layers.

The Off value correspond to the single-layer machining.

Monodirectional – multilayer machining, direction of passes on each layer equally.

Zigzag – multilayer machining, a root pass direction correspond the Machining direction, and the each following layer is opposite to the previous layer.

If multilayer is active then the Depth step defines the maximal distance to plunge the tool on each layer. It can be defined either by depth directly, or by number of layers.

Thread finishing group. If it is enabled, then finish passes are allocated along a threaded groove profile is set in the job assignment.

Finish step – step between the adjacent passes, calculated by the profile length. The step can be defined by count of passes or by distance directly.

The Machining direction parameter defines sequence of finish passes:

Forward.

Backward.

Bidirectional.