Transformation

<Transformation> – parameter's kit of operation, which allow to execute converting of coordinates for calculated within operation the trajectory of the tool.

On the page it is possible the setting of the following parameters:

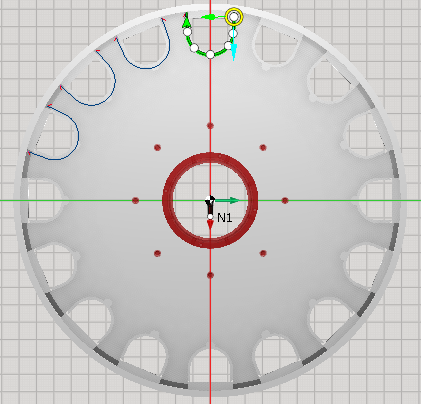

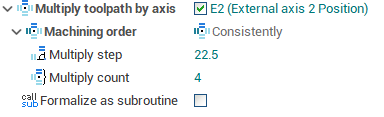

<Multiply toolpath by axis> allows to replicate the trajectory received on the computation of the operation in direction of one axle of the machine including rotary axle, if it presents in the machine.

T he coordinate system axle is selected in < Multiply toolpath by axis > field.

Machining order has 3 types:

<Consistenly> – repeating copies of a toolpath place along a circle, with the count and the angle step given in the appropriate field

< Most distant > – repeating copies of a toolpath place along a circle, with the count and the angle step given in the appropriate field. Elements are sorted more distantly from each other .

<Manually> – repeating copies of a toolpath place along a circle. The count and the angle of each element are set by user .

The following parameters can be set in multiply modes:

< Multiply Step > - step axle-direction in units within the given axle;

< Multiply Count > - quantity of block's repetitions;

<Steps> - quantity of block's repetitions with own angle

< Angle1..N > - angle of specific block's repetitions

<Formalize as s ubroutine > – the repeated block design as subprogram. A dditionally you can set its name in the field . If <Formalize as s ubroutine > is disabled, then the repeated block over and over again insert in CLData with re-calculated coordinates.

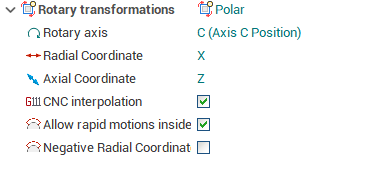

<Rotary transformation> – allow at 3-coordinate milling processing to change the displacement of the tool in direction of one of the linear axle to the rotary motion of the billet, if it is possible to execute on the machine.

The regime of converting is setting up in the field <Mode>:

<Polar>;

<Cylindrical>;

<Off>.

For interpolation the following parameters are setting:

The opportunity of executing by controller, setting with the help of the tick in the field <CNC interpolation>;

<Tolerance> characterize the deviation of transformed trajectory from ideal in millimeters (inches);

<Radial axis>;

<Rotary axis>;

<Axial axis>.

For cylindrical interpolation additionally set up the parameter <Cylinder radius>, on which the reamer of tool's movement is executed.

In addition to this method of copying, there is also Part Copies.

See also: