Check holder

The Check holder feature detects segments of the toolpath where the tool holder collides with the part and modifies those segments according with the specified strategy.

Strategies

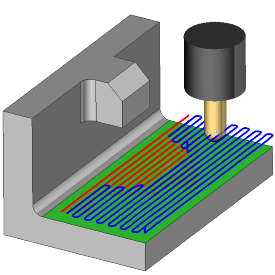

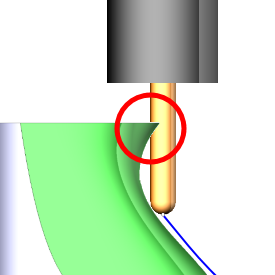

Trim toolpath

The colliding segments are excluded from the toolpath.

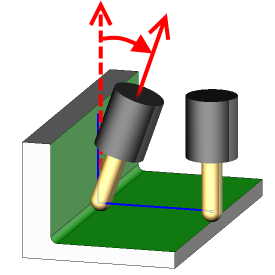

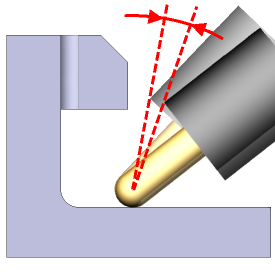

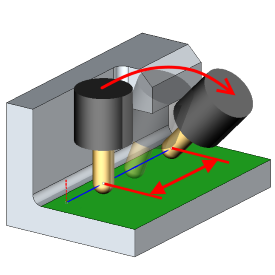

Frontal tilting

The tool tilts in the frontal direction to avoid collisions.

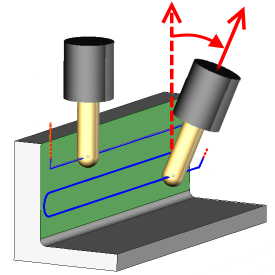

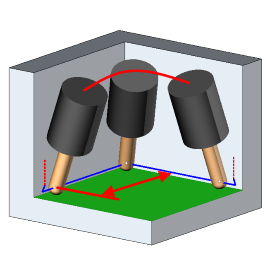

Side tilting

The tool tilts sideways to avoid collisions.

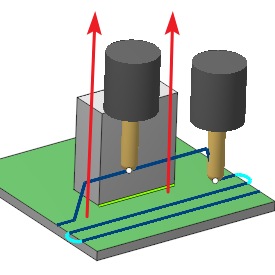

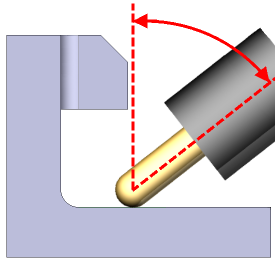

Offset along tool

The tool retracts along its axis to avoid collisions.

Parameters

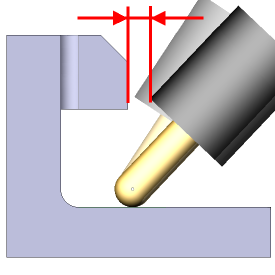

Clearance

The minimum allowed distance between the holder and the part.

Check tool

The option enables checking of the tool collisions alongside with the holder collisions.

Additional tilt angle

The additional clearance angle used for tilting to guarantee a safe collision-free toolpath. The greater the value is, the farther the tool tilts away from the collision.

Max. tilt angle

The maximum allowed tilting angle.

Smooth factor

The parameter controls smoothness of the tilting. The greater the value, the smoother the tilting is. 0 means no smoothing.

Blend distance

The blend distance is the distance between two points of the toolpath before and after the current tool position used for the calculation of the current tool movement direction which in turn is used to calculate the current tool tilting direction. Use greater values when machining irregular shapes with a lot of small bumps to eliminate unnecessary tool axis oscillations. Use values greater than the holder radius when machining inner corners.

See also: