Face milling

The face milling operation removes stock on a given horizontal plane with one of the following strategies:

One pass,

One way,

Zigzag,

Optimized zigzag,

Spiral.

The part geometry is ignored, only the workpiece geometry is taken into account. There is no gouge checking.

The stock can be removed in multiple Z-passes. The Final level of machining by default is the top most level of the part while the top level of machining is the top most level of the workpiece, but it is possible to override these values. The number of passes is determined automatically based on the given cleanup height and the depth step. However you can specify the number of Z-passes explicitly. In this case the depth step will be calculated based on the number of passes and the difference between the top and the final level of machining.

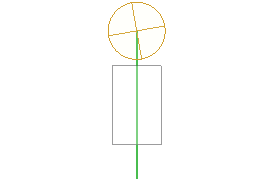

One pass strategy

The tool makes exactly one pass in the center of the workpiece. The work pass starts and ends outside the workpiece boundary.

Use this strategy when the diameter of the tool is bigger than the width of the workpiece.

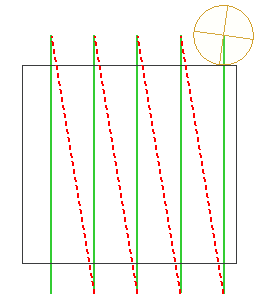

One way strategy

The tool moves in parallel passes always in one direction depending on the milling type (climb/conventional). A work pass starts and ends outside the workpiece boundary. The link moves are made on the safe plane.

With this strategy the best possible surface finish can be achieved.

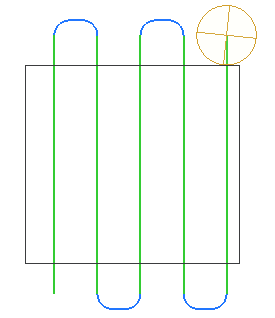

Zigzag strategy

The tool moves along zigzag trajectory. The work passes start and end outside the workpiece material. The link moves are made outside the material as well. A different feed rate may be used for the link moves.

The strategy is optimal for finishing face milling.

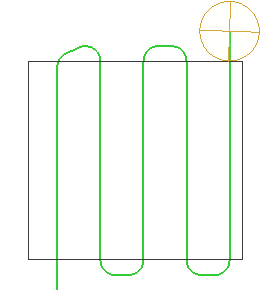

Optimized zigzag strategy

The tool moves along zigzag trajectory. The link moves between zig- and zag- passes are also made in-material on the work feed to reduce machining time.

The strategy is good for roughing and semi-finishing.

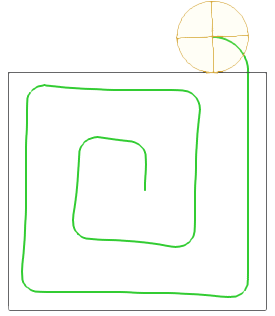

Spiral strategy

The tool rolls into the workpiece using the so-called roll-in technique, then moves along the boundary of uncut material removing it like a round lawn mower.

The maximum allowed width of cut and the tool engagement angle are never exceeded.

The strategy is very good for removing large volumes of material in minimal time.

Operation parameters

For more information on the operation parameters refer to the online help integrated into the operation parameters inspector.