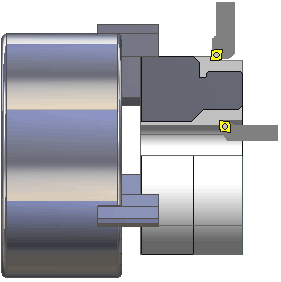

OD Roughing and ID Roughing operations

OD roughing, and ID roughing operations are designed to get the intermediate part by removing a lot of the workpiece volume that is located outside of the part and fixtures.

The tool removes material by the series of the parallel strokes. The strokes can be parallel or perpendicular to the revolution axis depending on using cycle type and its parameters.

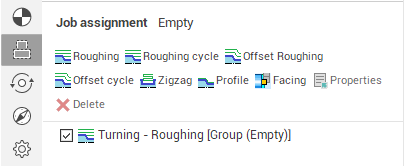

To define the working zone just open Job assignment page, select geometrical primitives that you want to machine and click to the button with the strategy you want to use. After that you can drag start/end point of contour on the screen directly to reduce job zone.

The following strategies allowed for roughing operations:

See the page of cycle parameters for detailed description of each strategy and Job assignment definition page for geometrical properties.

See also: