Hole machining operation

Whith

The hole machining operations are designed for drilling, centering, boring, countersinking, tapping, thread milling and hole pocketing. It can machine holes that are not lying in the same plane and that are not lying in orthogonal planes. The operation can be used both for the machining of holes in a model, or for pre-drilling of the tool plunge points for the pocketing and waterline roughingwaterline roughing operations. For this, the system will use either user defined drill points, or points generated automatically by the waterline operations. The list of holes can also be created automatically from a geometrical model using the holes recognition function.

For drilling the tool plunge points during pocketing and waterline-roughing operations it is necessary that when creating a hole machining operation the user define the operation prototype for which to perform the pre-drilling. The prototype operation will contain the list of drilling points and their depth for the hole machining operation.

Holes can be automatically recognized, selected and added through graphic interface, specified by center points or by manual coordinate input. Coordinates for holes centers are assigned by points, which can be imported from files or defined in the 2D geometry mode. The list of points with their parameters (Z rapid height and drilling depth) is formed in the Job assignment window. In the same window the user can access the function of automatic recognition of holes in the model.

The hole top level and bottom level for every point can be assigned by the user or calculated automatically. When the top level is calculated automatically, it will be determined according to the workpiece model, and the bottom level definition based on the model being machined.

In most cases the diameter of the tool should be defined equal to the diameter of holes. And when machining holes by spiral and circular strategies, the diameter of the tool should be smaller than the hole diameter. All holes of an operation are machined using one tool and one cycle. To machine holes of different diameter or different types of cycles one should create several operations. Excluded from this are the spiral and circular machining options.

Use operation parameters dialog that is accessed by the  button on the <Machining> tab to setup general operation properties. Use the <Tool> tab to select the tool for hole machining.

button on the <Machining> tab to setup general operation properties. Use the <Tool> tab to select the tool for hole machining.

Use <Feeds/Speeds> tab to setup cutting conditions: spindle revolution rate, cooling, feed rates for different motion modes(approach, retract, work feed and the like). Auxiliary transitions (non-cut transitions) are performed either with rapid feed rate or with work feed rate, this option is controlled by the <All non-cut feeds as rapid> check-box. Work feed rate motion for non-cut transitions is useful then machining non-orthogonal plane holes as some NC-systems control only the start and end positions of the tool when performing rapid motions.

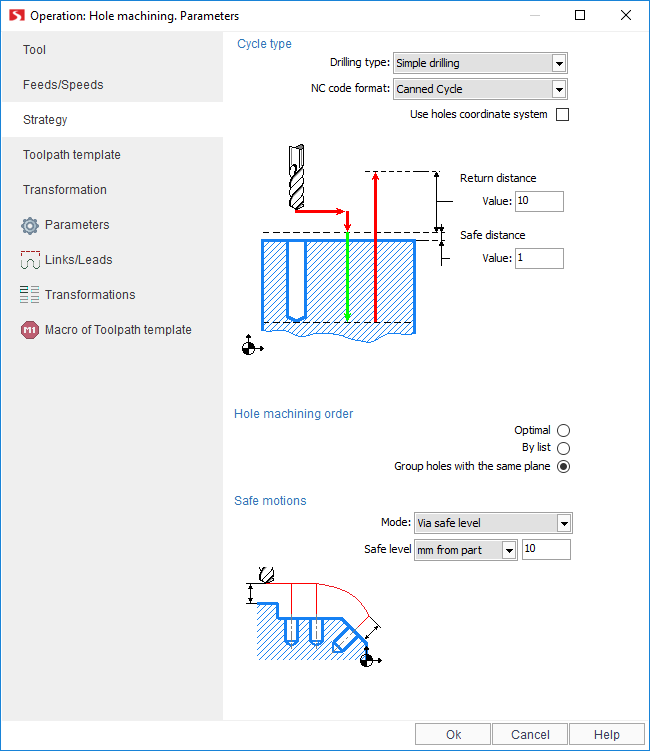

Hole machining mode and other additional parameters are set on the <Strategy> tab.

The dialog interface and parameter list change according to selected <Drilling type>.

NC code format defines the way of the g-code output:

<Long Hang>. All motions are output as the elementary command (lines and circle arcs). Use this option for special cases then machine's CNC-system can't form canned cycle movements (for example, some CNC-systems do not support canned cycles at non-orthogonal planes).

<Canned cycle>. The cycles is output. Every cycle contains a full set of motions to machine the hole within itself. The way of machining depends on the used CNC. See your CNC manual for the detailed information.

if <Use holes coordinate system> is off then alll holes machined in the operation coordinate system. If <Use holes coordinate system> is on then the <ORIGIN> command is output before the hole machining. So every hole is machined with it's own local coordinate system. Read the operation coordinate system topic for detailed information about <ORIGIN>. So the hole machining cycle is applied for the XY plane. Most of the CNC supports the cycles in this plane.

The order of the holes machining depends on the order in the job assignment list if the <Hole machining order> is set to <By List>. if optimal is selected then SprutCAM minimizes the length of the idle motions. If <Group holes with the same plane> item selected then system will optimize machining order inside groups of holes that lie at the same planes.

The parameters on the <Safe coordinate> panel defines the way of the transition from the one hole to the next one. With the <Mode> drop-down list system allows you to select the following types of transitions.

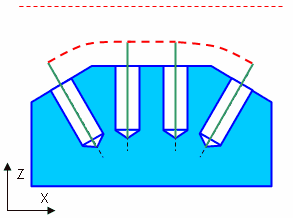

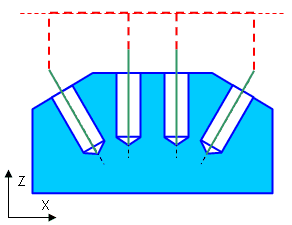

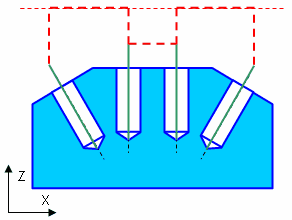

<Use safe level> Transition generated by this method consists of moving to the safe level of current hole, straight moving to the safe level of the next hole and moving to its cycle start level. It should be noted that the safe level is always measured along the axis of each of the machined holes. The value of a safe level can be specified either as an absolute or as a relative value. With absolute way the level is measured from the projection of the coordinate system's origin to the axis of the hole. With the relative way of defining the level measured along the axis of the hole, from the highest point of the entire part.

|

Absolute safe level |

Incremental safe level |

|

|

|

<Never> The going up on the safe coordinate is never performed. The approach to each hole is performed directly to the <Return point>.

<Always> Transition is executed via safe coordinate along the axis which is selected in the drop down list below on the same panel. The moving to the safe coordinate is always performed for each hole.

<When orientation changed>. Transition is executed via safe coordinate along the axis which is selected in the drop down list below on the same panel. The going up on the safe coordinate is performed only if the hole axis direction is different. In two holes located on the same plane then the transition is performed directly form first return point to the second one.

The <Safe distance> parameter defines dimension from the upper level of the hole to the point on the hole axis. The feedrate is switched in this point from the rapid to the work one. So this distance is used to avoid the collision on the rapid feed.

<Return distance> defines the <Return point> under the hole. It is the distance from the upper hole level to the point on the axis. This is the start and end point of the hole machining cycle.

For the spiral (thread milling) and hole pocketing cycles it is possible to generate the g-code with the radius compensation. The radius compensation works like in other operations.

Multiply tool path by axis simplifies the machining of the repeated part holes. It works like in other operation.

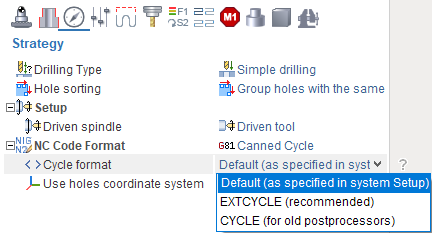

For compatibility with older versions of postprocessors the system provides the ability to change the output format of the drilling cycle (when not expanded toolpath output method is used). In the properties inspector for the hole machining operation is a corresponding parameter <Format cycle>.

This parameter can have the following values.

<Default (as specified in system Setup)>. The cycle format will be used, which is specified in the system settings. The default setting in the system Setup window has a value EXTCYCLE.

<EXTCYCLE (recommended)>. The new format of the cycle EXTCYCLE will be used. This cycle has an advanced set of parameters, including all machining strategies that are implemented in the system, and allows a realistic simulation of the tool movements according to the chosen strategy.

<CYCLE (for old postprocessors)>. The old format of the cycle CYCLE will be used. This cycle cannot be used for some of the strategies available in the system (e.g., hole pocketing or machining by spiral). Also this cycle simulates any machining strategy only as a simple movement to the lower level of the hole. This format is required for compatibility with older versions of postprocessors, where EXTCYCLE technological command processing routine is not implemented.

See also:

Operation for 2/2.5-axes milling

The ways of the holes machining